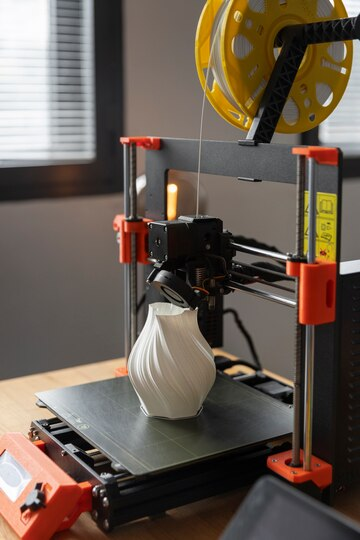

The advent of 3D Print Service innovations has marked a pivotal turning point in the manufacturing industry. This technology is not just altering production methods; it’s reshaping the entire approach to design, prototyping, and fabrication. With its capacity for customization, rapid prototyping, and cost efficiency, 3D print services in Malaysia are revolutionizing traditional manufacturing paradigms and paving the way for a more agile, innovative future.

Customization at the Forefront

One of the most significant impacts of 3D print services is the unparalleled level of customization they bring to manufacturing. Unlike traditional methods, where customization can be time-consuming and costly, 3D printing allows for individualized production without additional costs. This ability to tailor products to specific customer needs is transforming industries from healthcare to automotive, offering personalized solutions that were previously unimaginable.

Speed and Efficiency in Prototyping

3D print services have dramatically accelerated the prototyping process. Where traditional prototyping methods could take weeks or even months, 3D printing achieves this in a matter of days or hours. This rapid turnaround time enables manufacturers to iterate designs quickly, test ideas more efficiently, and bring products to market faster than ever before.

Reducing Waste and Environmental Impact

A key advantage of 3D printing is its contribution to sustainability. Traditional manufacturing often results in significant waste, but 3D printing minimizes this by only using the material necessary to build the part. This efficient use of resources not only reduces waste but also lowers the environmental impact, aligning manufacturing processes with the growing need for sustainable practices.

Cost-Effective Production for Small Batches

Another area where 3D print services are making a substantial difference is in the production of small batches. Traditional manufacturing methods are geared towards mass production and can be prohibitively expensive for small runs. 3D printing, on the other hand, makes small batch production economically viable, opening up new opportunities for small businesses and startups.

Challenges and Future Prospects

Despite the numerous benefits, 3D print services also face challenges. These include the limitations in materials, the need for skilled operators, and concerns about the strength and durability of 3D printed products compared to those made with traditional methods. However, ongoing advancements in technology are continuously addressing these challenges, expanding the capabilities of 3D print services.

Conclusion

3D Print Service innovations are undeniably transforming the manufacturing industry. They are redefining the limits of what is possible in production, from delivering unparalleled customization to enhancing speed and efficiency, all while promoting environmental sustainability. As technology continues to advance, the potential for 3D print services in manufacturing seems boundless, promising a future where flexibility, efficiency, and innovation are at the heart of production. The impact of these services is not just a shift in manufacturing techniques; it’s a fundamental change in the approach to product development and production, signaling a new era in the manufacturing industry.